Cp stands for process capability and Cpk stands for process capability index. Both are used for the measure of a potential capability of a process in short term. The higher the sigma level, the better the process is performing. You can learn how to calculate Cp and Cpk values using this tutorial. Learn to calculate the Process Capability (Cp) and Process Capability Index (Cpk) values using the steps and few examples given here.

My customer wants to know if my process is capable of meeting their specifications and is in statistical control. My boss needs the process capability for the monthly report. I would like to track all the Cpk and Ppk values of my processes? My data are not normally distributed; I need a non-normal process capability analysis. See What Process Capability in SPC for Excel. Cpk Calculator is a free online tool that displays the process performance for the specified range. BYJU’S online Cpk calculator tool makes the calculation faster, and it calculates the performance of the. Beyond Excel: Control Plan with monday.com Mike Walton (10/20) Fishbone Diagram Excel Template by Del Simcox (10/20) SWOT Analysis by Del Simcox (10/20) DPMO and Sigma Level Calculation - Excel Template (10/20) Project Charter Template with Financials (9/20) Project Charter Example - New Product Intro; Implementation Plan Template by Del Simcox.

Learn to Calculate Process Capability Index - Tutorial, Definition and Example

Process Capability (Cp) Definition:

Process capability is a technique to find out the measurable property of a process to a specification. Generally, the final solution of the process capability is specified either in the form of calculations or histograms

Process Capability Index (Cpk) Definition:

Process capability index (cpk) is the measure of process capability. It shows how closely a process is able to produce the output to its overall specifications.

Formula :

Where,

USL = Upper Specification Limit, LSL = Lower Specification Limit.

Example :

Food served at a restaurant should be between 38°C and 49°C when it is delivered to the customer. The process used to keep the food at the correct temperature has a process standard deviation of 2°C and the mean value for these temperature is 40. What is the process capability of the process?

Given,

USL (Upper Specification Limit) =49°C LSL (Lower Specification Limit) =39°C Standard Deviation =2°C Mean = 40

To Find,

Process Capability & Process Capability Index

Solution:

| Process Capability : | |

|---|---|

| Process Capability | = (49 - 39) / (6 * 2) |

| = 10 / 12 | |

| = 0.833 | |

| Process Capability Index : | |

| Solution 1 | |

| (USL-mean/ 3*std.Dev) | = (49 - 40) / (3 * 2) |

| = 1.5 | |

| Solution 2 | |

| (mean-LSL/3*std.Dev) | = (40 - 39) / (3 * 2) |

| = 0.166 | |

| Now, find the minimum value. | |

| Process Capability Index | = min (Solution 1, Solution 2) |

| = min (1.5 , 0.166) | |

| = 0.166 | |

Cp and Cpk are used in Six Sigma Quality Methods for analyzing the performance of the process carried out to deliver any product.

Related Tutorials:

Top Calculators

Popular Calculators

Top Categories

Gage R&R (Gage Repeatability and Reproducibility) is the amount of measurement variation introduced by a measurement system.

A Gage R&R study is a critical step in process improvement projects, and it quantifies three things –

- Repeatability – variation from the measurement instrument

- Reproducibility – variation from the individuals using the instrument

- Overall Gage R&R, which is the combined effect of (1) and (2)

The overall Gage R&R is normally expressed as a percentage of the tolerance for the CTQ being studied, and a value of 20% Gage R&R or less is considered acceptable in most cases. Example: for a 4.20mm to 4.22mm specification (0.02 total tolerance) on a shaft diameter, an acceptable Gage R&R value would be 20 percent of 0.02mm (0.004mm) or less.

The Difference Between Gage R&R and Accuracy (Bias)

A Gage R&R study quantifies the inherent variation in the measurement system, but measurement system accuracy (more specifically referred to as bias) must be verified through a calibration process. For example, when reading an outdoor thermometer, we might find a total Gage R&R of five degrees, meaning that we will observe up to five degrees of temperature variation, independent of the actual temperature at a given time. However, the thermometer itself might also be calibrated ten degrees to the low side, meaning that, on average, the thermometer will read ten degrees below the actual temperature. The effects of poor accuracy and a high Gage R&R can render a measurement system useless if not addressed.

Measurement system variation is often a major contributor to the observed process variation, and in some cases it is found to be the number-one contributor. Remember, Six Sigma is all about reducing variation.

Think about the possible outcomes if a high-variation measurement system is not evaluated and corrected during the Measure phase of a DMAIC project – there is a good chance that the team will be mystified by the variation they encounter in the Analyze phase, as they search for variation causes outside the measurement system.

Measurement system variation is inherently built into the values we observe from a measuring instrument, and a high-variation measurement system can completely distort a process capability study (not to mention the effects of false accepts and false rejects from a quality perspective). The following graph shows how an otherwise capable process (Cpk = 2.0: this is a Six Sigma process) is portrayed as marginal or poor as the Gage R&R percentage increases:

Conducting a Study

GR&R studies can be conducted on both variable (gaging that produces data) and attribute (gaging that produces a “go/no-go” result) gaging. Prior to conducting a Gage R&R, the following steps/precautions should be taken –

Calibrate the gage – ensure that the gage is calibrated through its operating range – keep in mind that Gage R&R and gage accuracy are two different things.

Check the gage resolution – the gage should have sufficient resolution to distinguish between several values within the tolerance range of the feature being measured. As a general rule, the gage should be able to distinguish at least ten readings within the tolerance range. See distinct categories for more information.

Collect samples to be measured – it’s important to collect samples (parts, materials, or whatever is being measured) that represent the majority of the variation present in the process. Sometimes it is helpful to have inspectors set aside a group of parts that represent the full spectrum of measurements. Ten samples are considered a good number for a Gage R&R study in a manufacturing environment.

Plan for within-product variation if necessary – sometimes the same characteristic can be measured in multiple locations on the same sample, and in these cases it’s a good idea to mark the item being measured to indicate where the measurement should take place. For example, if the diameter of a washer is being measured, the roundness of each washer in the study could affect the Gage R&R results, so mark the location on each washer where the diameter measurement should be taken. The same guideline applies to things like color measurements, where within-part color variation can overshadow the measurement system’s performance. Once again, clearly note the location on the sample where the color should be measured.

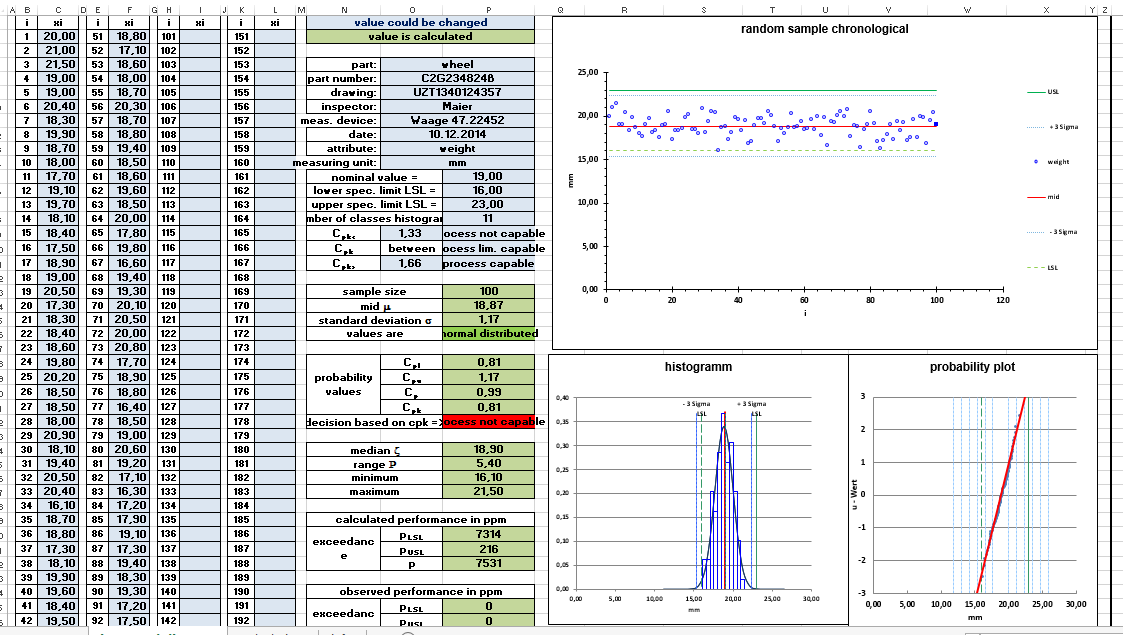

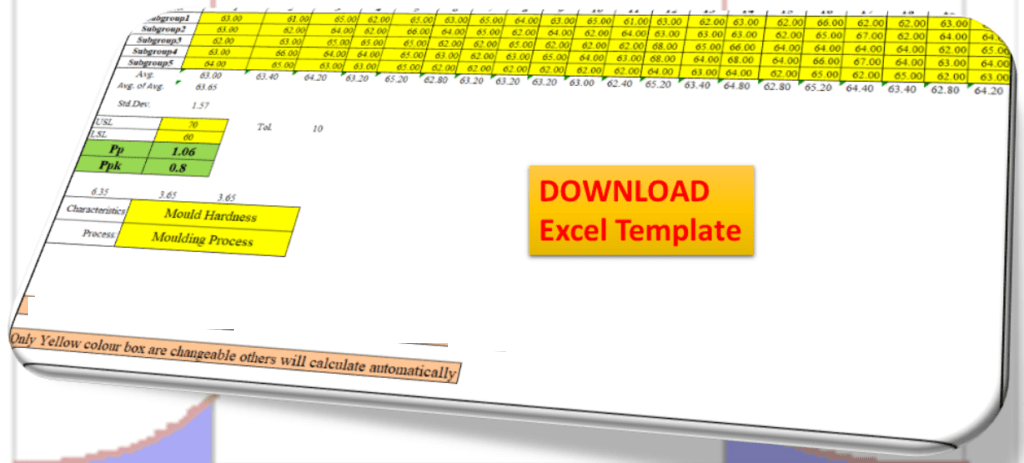

Cpk Calculation Excel Download

Identify operators – a Gage R&R study can be done with two operators, but a minimum of three operators is recommended for a meaningful study. Also make sure that at least one of the operators is an individual who will interpret the gage during normal production operations.

Document the measurement method and train the operators to follow it – this can save the team from having to repeat the study.

Plan for randomization – it’s important to randomize the sequence of measurements (who measures which part, and when), to block the effects of uncontrollable factors that might otherwise be attributed to specific operators. Each operator should measure each part three times, so with ten parts a total of 90 measurements will be taken.

Cp Cpk Calculation Excel Sheet

Excel Template

Here is a Gage R&R Excel template with that produces the graphs shown below . Calculations have been verified with AIAG examples.

How Much Gage Variation is Acceptable?

Reducing Measurement System Variation

If the Gage R&R is greater than 20% (see guidelines above), then the measurement device and/or the measurement method will need to be addressed. The following charts are useful in diagnosing excessive measurement system variation:

Cpk Calculation Excel Spreadsheet

A word of advice to quality leaders: always ask to see a GR&R study before accepting the results of a process capability study. For an in-depth review of Gage R & R and overall measurement systems analysis (MSA), purchase a copy of the Automotive Industry Action Group’s MSA guide – this is an outstanding publication.

Cpk In Excel Formula

1 See AIAG, Measurement System Analysis, Third Edition, Page 7